Making Cider with Rat Patrol UK Cider is intrinsic to the Rat Patrol UK. The chapter is based in Ross-on-Wye, Herefordshire, and Rats work year round at Broome Farm to produce enough booze to keep them drunk for the next chopping season. Indeed, this is the way it always was, for all people worldwide, until Temperance and large corporate breweries took alcohol out of the hands of the people and made them pay for what should be free. Have you ever picked up 500 beer cans after a party and thought that something wasn't quite right about the way we purchase and consume alcohol? Why does the beer come in 500 disposable containers instead of one large reusable one? Why do we pay per six pack rather than the bulk cost of one keg? Why, indeed, don't we make our own alcohol? In America we have a folk hero by the name of Johnny Appleseed, who planted cider orchards all over the country. Unfortunately during Prohibition those orchards were mostly burnt down at large Temperance-based orchard-burning parties, and America's cider culture has never recovered. Still, with the popularity of ornamental apple trees around turn-of-the-century Chicago, there may be chance yet again for local cider. Some founding Rats have already begun to brew Rat Patrol brand beer at a significantly reduced cost, around $17 per 50 gallons. Our Ghana chapter ferments its own palm wine simply by tapping a tree and letting it sit in the hot jungle for a few hours. Only those blinded by civilization haven't caught on that a "drinking club with a bicycle problem" should make its own booze as well as its own bicycles. You can make cider yourself, if you can get some apples- it's really not much more than squeezing the juice and putting it into a barrel and then waiting. The ornamental use of apple trees in Chicago around the turn of the last century makes Chicago 'ripe' for urban cider production. Pruning

At the beginning of the cider's life span, the trees must be pruned. This is a dirty task and can take months on a farm like Broome Farm with 10,000 apple trees. Still, the orchard is a quiet misty place, full of peace and the occasional hedgehog or badger. Broome farm also has 100 pear trees and makes pear cider aka Perry. Picking

You can taste when the apples are ready to be picked. You want all the starch in them to be converted to sugar. At a farm like Broome, the apples are shaken from the tree with a belt and picked up with a special tractor. Different kinds of apples make different cider- if you've got dessert apples (sweet ones), you can mix them with crabapples to balance the cider. American hard cider has sugar added, and it tastes like apple juice. One crusty old cidermaker told me "American cider's never seen an apple! They just tap the barrel with one after it's made!" Indeed, the varieties available in America (Strongbow, Woodchuck, and K) are far from authentic. If it tastes like apple juice with bubbles, it's basically apple beer pop. If it tastes dry and clean, it's cider. When it starts to get really boozy and taste like nail polish, you've gotten into scrumpy. Scratting and pressing

Bennito Chunkolini Prince of Darkness and Mr. M23 load the next layer of apple chunks into the press while Tallmartin picks up the next bushel.

The general rule is that 80 3-gallon buckets of apples produces 150 gallons of juice. On a smaller scale, ten 3-gallon buckets (or six 5-gallon buckets) will give you about 18 gallons of juice. You can pick up a nice used whiskey or rum cast if you're up for making 50 gallons of juice, and the first batch will have the flavor from the liquor. You can also get reconditioned food-grade plastic drums, but I'd stay away from used industrial barrels for obvious reasons. Still, they alley behind any fast food place will yeild plenty of used 5-gallon food buckets and you can make just a bucket of cider if you'd like. You want to sterilize the container- bacteria will convert your cider to vinegar, which will still be useful but won't get you drunk. Generally you can't buy juice for this because current food regulations require orchards to pasteurize it before sale, but some old country places might slip you some if you'd like to skip this step entirely.

Scratting and pressing is probably the most difficult part for the amateur cidermaker- you need to bust up the apples into chunks and then press the juice out with some mechanical method. At the farm we put the apples through a scratter and then wrap them up in cheesecloth between wooden slats, using a hydraulic press to squeeze all the juice out. I've heard of folks just doing it by driving over a bag of apples with a car, so perhaps you can gussy something up. Also cider farms charge to scrat and press the cider for you if your scale is big enough to justify the cost. Fermenting

The natural yeasts in the apple juice will ferment the cider. Here you want it to be able to burp off gas without exposing the juice to air (where bacteria will spoil it). A bung with an airlock is a simple thing, it just needs a pipe from the barrel going down into a cup of water so bubbles are forced in but can't go back, just like a wee bong. If you really wanna get pro, you can add a little tiny bit of sodium metabisulfite, an additive available from home-brew shops. The simplest method is to put it in a bucket, set the lid on loosely, and burp it a few times a day.

When all the sugar is converted to alcohol, the bubbles will stop. The cider will be clear and taste dry and not sweet. It's time to lock down the barrel (usually transferring into another container to leave the solids and dead yeast cells behind) and wait till Christmas. The cider should sit in a cool place like your basement.

Bottling

Once a container of cider is opened, it should be consumed within a fortnight. You may find it best to rack it into several different sizes of bottles- wine bottles for a night's consumption, jugs for a dinner, buckets for a party. Drinking the cider

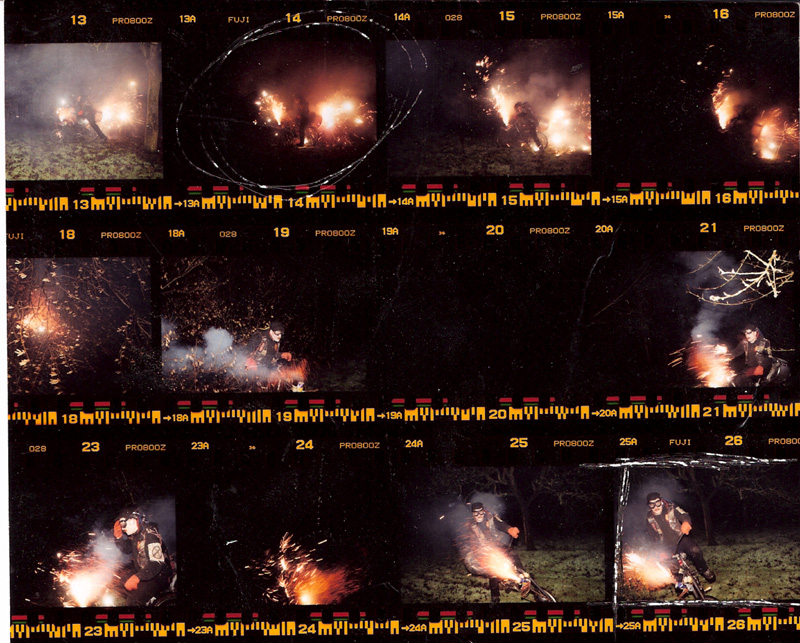

Cider has been made at Broome Farm for over 200 years. Different varieties of apples in different concentrations are always being used to come up with the best cider. This process requires dedicated, daily consumption of cider after the farm work is done. The three qualities of cider are dryness, bitterness, and sharpness. Dryness is the absence of sugar, bitterness is caused by tannins, and sharpness is the presence of acid. The best ciders are well-balanced and often we combine from several casks to make the perfect glass of cider. WassailingBy Christmastime, both you and the cider are ready to be drunk. Now comes the most important part: Wassailing. The community shares a bowl of cider and marches around the orchard with torches, making as much noise as possible to scare off bad spirits. Cider-soaked toast is hung from the trees to please the pixies who live in and care for them. Here's a history of wassailing from the Broome Farm website: Wassailing the cider orchards is one of the most important events of the farming year since it is widely regarded as essential if disaster was not to befall the precious crop.The Rat Patrol UK practices traditional wassailing methods, however, the modern invention of the bicycle has allowed us to vastly improve our spirit-scaring technology. Choppers are loaded with explosives and ridden around the bonfire in the orchard.

|